AiD

Any Industrial Data

Industrial Data Acquisition

Data Loss Prevention

Web Interface

Cloud Solution

Open Data Format

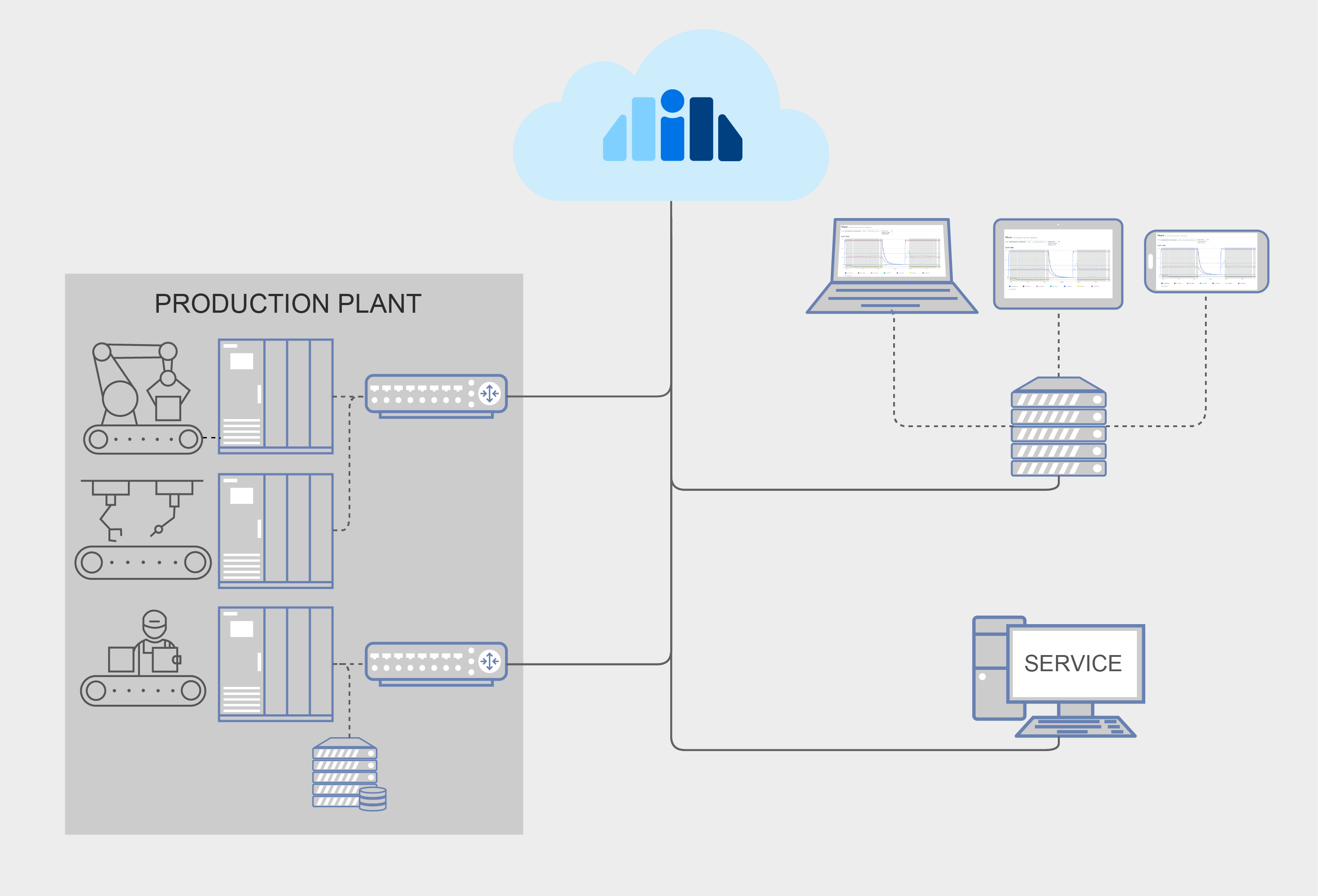

Scheme

Why AiD?

Analyzing OEE and productivity

You can analyze your data to see any delays and micro-stops in your production. Then you can focus on optimizing your process. Thanks to real-time data, you can react immediately.

Technology parameters

In the stored data it is possible to trace back the machine parameters at a given moment. This way you can always control the machine and the quality.

Energy consumption

Monitor and optimize energy consumption with AiD. With accurate data, you can reduce the consumption of your entire plant.

Back-tracing parts

AiD stores production data (temperatures, pressures, times, ...) for each part produced. An individual part has a unique ID so that each part can be traced back and you can view its production data. You can use this information for reporting to the customer, for example.

Analyzing input materials

Since the AiD is monitoring consumption of any input material, you can analyze how much of this material is used for one product and optimize it.

From operator to CEO

Visualization is useful for both the machine operator and the plant director. The operator can check the production parameters and the director has an overview of the production.